Working with Suppliers

This section explains working with suppliers, covering managing stock, interpretation of bar gate stock graphs, just-in-time (JIT) stock control, relationships with suppliers, the impact of logistics and supply decisions on businesses.

Managing Stock

https://revisionworld.com/gcse-revision/business-studies/production/sto…

Stock refers to the materials, components, or finished products a business holds. Effective stock management ensures that businesses:

- Have enough stock to meet customer demand without overstocking.

- Avoid the costs of storage and wastage.

- Prevent production delays caused by stock shortages.

There are three types of stock:

Raw materials – inputs required for production.

Work-in-progress – semi-finished products.

Finished goods – completed products ready for sale.

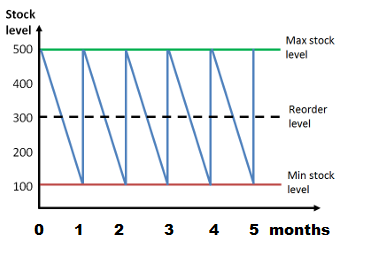

Interpretation of Bar Gate Stock Graphs

A bar gate stock graph is a visual tool used to monitor stock levels over time. Key terms include:

Maximum stock level: The highest amount of stock a business can hold.

Reorder level: The stock level at which new stock is ordered to prevent a shortage.

Lead time: The time taken between placing an order and receiving the stock.

Minimum stock level (buffer stock): The lowest amount of stock a business aims to keep to avoid running out.

How to interpret bar gate stock graphs:

When stock falls to the reorder level, new stock is ordered.

The graph above shows the stock level decreasing monthly as it is used and replenished after delivery.

If the lead time is too long, the business risks running out of stock, which can disrupt operations.

Just-in-Time (JIT) Stock Control

JIT is a stock control system where materials and goods are ordered and delivered just as they are needed. This minimises the need to hold large quantities of stock.

Advantages of JIT:

- Reduces storage costs: No need for large warehouses.

- Minimises waste: Stock is only ordered when required.

- Improves cash flow: Less money is tied up in stock.

- Encourages efficiency: Production is closely aligned with demand.

Disadvantages of JIT:

- Reliance on suppliers: Delays can halt production.

- No buffer stock: Unexpected demand cannot be met easily.

- High risk of disruptions: Any issues in logistics or supply chains can cause significant problems.

Relationships with Suppliers

Strong relationships with suppliers are crucial for the smooth operation of a business. Key aspects of good supplier relationships include:

Reliability: Suppliers must deliver goods on time to avoid production delays.

Quality: High-quality materials ensure the final product meets customer expectations.

Communication: Clear communication helps avoid misunderstandings and errors.

Fair payment terms: Prompt payments encourage suppliers to prioritise the business.

A strong relationship with suppliers can result in preferential treatment, such as priority delivery or discounts for bulk purchases.

The Impact of Logistics and Supply Decisions on Businesses

Costs:

- Efficient logistics (e.g., optimised delivery routes) reduce transportation costs.

- Bulk buying reduces unit costs but requires more storage space, increasing holding costs.

- Poor supply chain decisions, such as relying on distant suppliers, can increase expenses due to shipping fees and tariffs.

Reputation:

- Reliable delivery of products enhances a business's reputation.

- Late or inconsistent deliveries can damage relationships with customers and suppliers.

- Ethical sourcing (e.g., using environmentally friendly materials) can improve brand image.

Customer Satisfaction:

- Quick and consistent delivery ensures customers receive products when expected.

- High-quality materials lead to better products, which increases customer loyalty.

- Stockouts (running out of stock) can frustrate customers and lead to lost sales.

By understanding these aspects, businesses can ensure their supply chains run smoothly, maintain strong relationships with suppliers, and balance costs, reputation, and customer satisfaction.